Cosmetics OEMs require a range of equipment to facilitate the manufacturing process. First and foremost, a crucial piece of equipment is a mixer or loader. This mixer or loader is used to mix and blend raw materials, ensuring even distribution of ingredients. This helps produce high-quality cosmetics with a smooth texture and easy application. Secondly, cosmetics OEMs require temperature control equipment, such as heating and cooling systems. These devices help control the temperature of cosmetics, ensuring they are manufactured and stored within the correct temperature range. Another essential piece of equipment is a mixer or loader, which is used to thoroughly blend the various ingredients to achieve the desired formula.

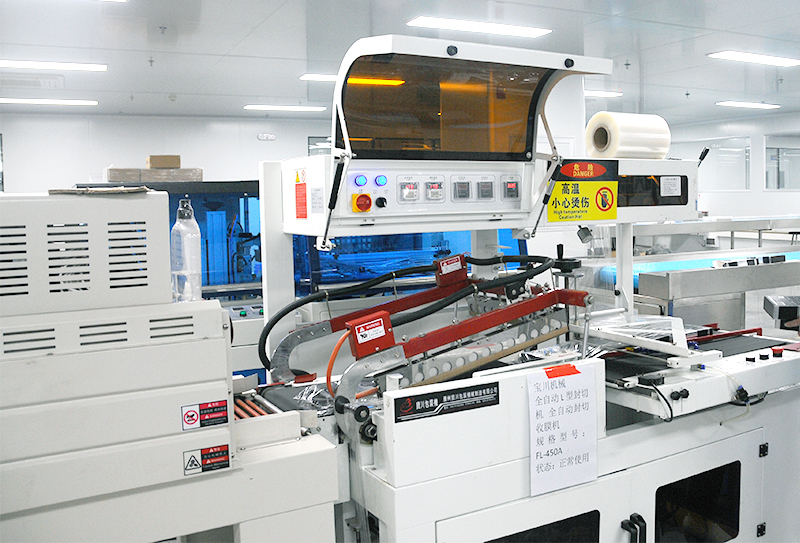

Mixers ensure uniform texture and color. Furthermore, cosmetics OEMs require packaging equipment, such as filling machines, labeling machines, and sealing machines. These machines are used to fill, seal, and package cosmetics into appropriate containers. Finally, a crucial piece of equipment is quality inspection equipment. Quality inspection equipment ensures that cosmetics meet quality and safety standards. It checks for ingredients, pH levels, and microbial contamination to ensure product quality and safety. In summary, cosmetics OEMs require a range of equipment to facilitate the manufacturing process, including mixers or loader, temperature control equipment, mixers, packaging equipment, and quality inspection equipment. The use of these devices can ensure the quality and safety of cosmetics manufacturing.